Introduction

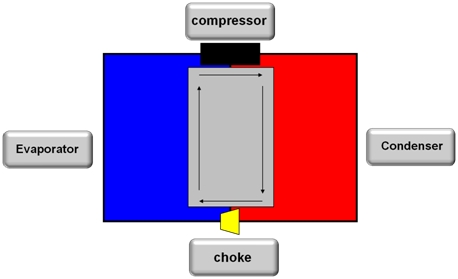

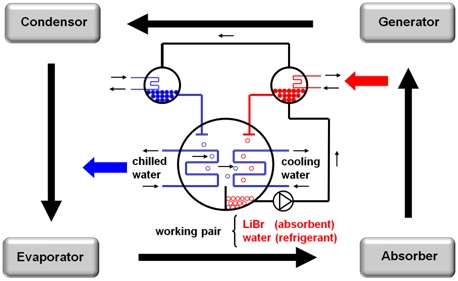

Sorption cooling is a less know alternative cooling technology to compression cooling. Other than compression cooling that uses compression and expansion of gases for the generation of coldness, sorption cooling generates coldness by evaporation of a solvent that is then adsorbed into another medium.

The applied adsorption medium has to show a high affinity towards the evaporation solvent. The two components adsorption medium and solvent form the so called working pair. Typically working pairs like lithium bromide/water, lithium bromide/ammonia or zeolithes/water are used.

The application of ionic liquids in sorption cooling devices was first described by the founders of IOLITEC:[i] The basic idea was to replace previously used orption media by ionic liquids since these

- Have a negligible vapor pressure

-

Are liquid over a wide temperature range and

-

Can be designed to have a high affinity against the evaporating solvent and to be non corrosive or corrosion inhibitors

Already in 2005 IOLITEC sold the rights to this technology to BASF SE.

If you are interested in this technology, please also contact BASF SE.

Nevertheless IOLITEC still continues to conduct fundamental research in this interesting application in joint projects[ii]. Currently the development of new improved sorption cooling media is IOLITEC’s focus. [iii]

If you are interested in further information, please contact us.

Text: Dr. Thomas J. S. Schubert, IOLITEC GmbH, 2011. (German Version; English Translation: Dr. Tom Beyersdorff, IOLITEC Inc.)

[II D2]

[i] A. Bösmann, T. J. S. Schubert, German Patent, DE102004024967, BASF SE, 2004.

[ii] a) Projekt „Entwicklung einer Absorptionskältemaschine für den Betrieb mit einem Arbeitsstoffpaar Wasser – Ionische Flüssigkeit“, gefördert durch die Deutsche Bundesstiftung Umwelt e.V. (www.dbu.de); Partner: Institut für Technische Thermodynamik und Kältetechnik des Karlsruher Instituts für Technologie, Arbeitsgruppe Prof. Dr.-Ing. K.H. Schaber (www.ttk.uni-karlsruhe.de) und IPF Beteiligungsgesellschaft Berndt KG, Reilingen.

b) Projekt „Nutzung von Niedertemperaturwärme durch Absorptionskreisläufe zur Kälteerzeugung und Wärmetransformation – Einsatz von neuartigen Arbeitsstoffpaaren“; Partner: Institut für Technische Thermodynamik und Kältetechnik des Karlsruher Instituts für Technologie, Arbeitsgruppe Prof. Dr.-Ing. K.H. Schaber (www.ttk.uni-karlsruhe.de); BASF SE, Ludwigshafen; API Schmidt-Bretten GmbH & Co. KG, Bretten (www.apischmidt-bretten.de).

[iii] D. Constantinescu, K.-H. Schaber, F. Agel, M. H. Klingele, T. J. S. Schubert, J. Chem. Eng. Data 2007, 52, 1280.