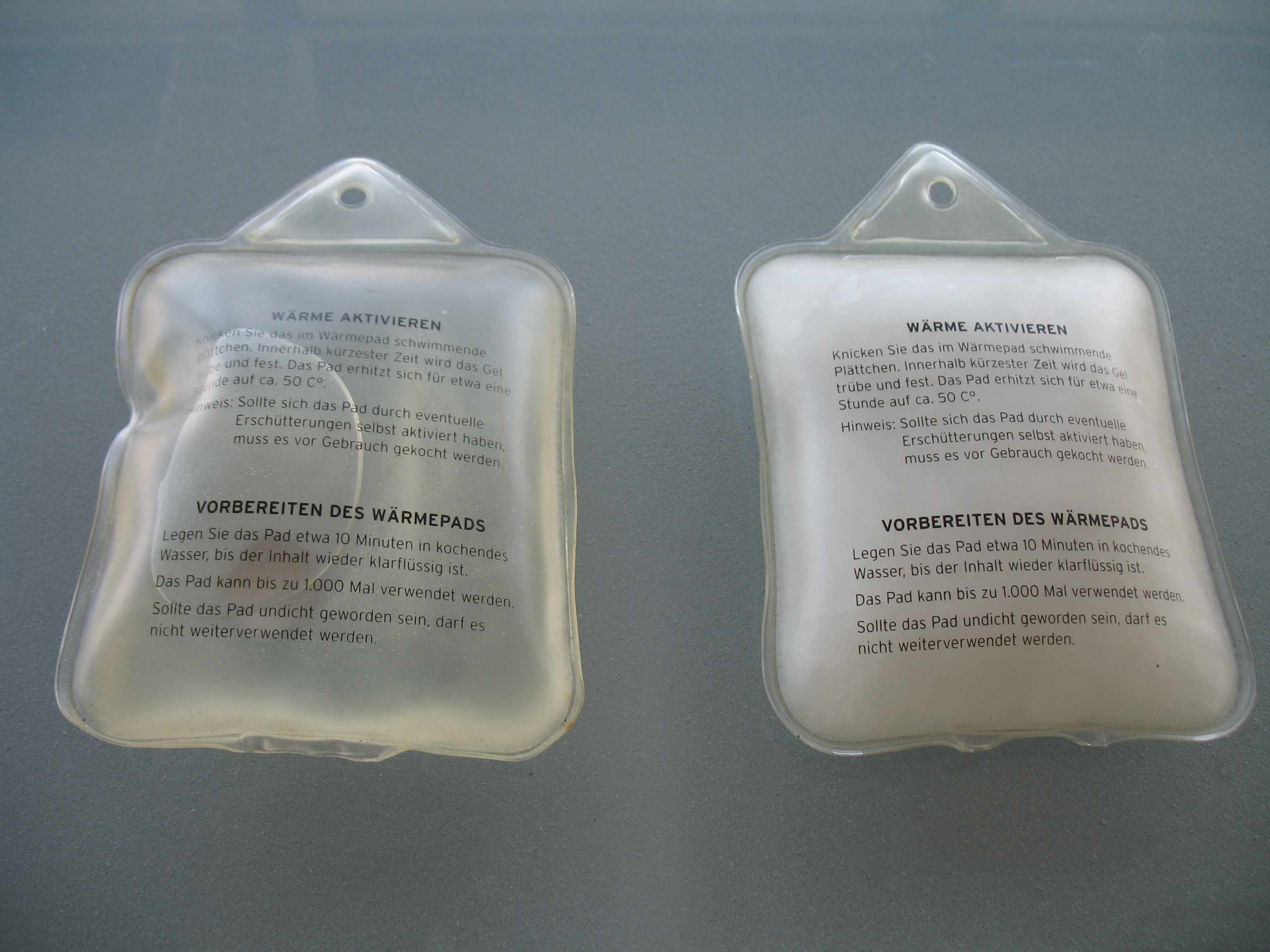

Probably the most prominent example that uses phase change materials is heat packs or pocket warmers. They consist of a bag filled with a supersaturated salt solution (typically sodium acetate). The clicking of the small metal plate initiates the crystallisation of supersaturated solution proceeding with the release of heat. The bag can be regenerated by heating it in a pot with boiling water - the solid liquefies (salt dissolves) and the heat pack can be used again.

Figure 1. Pocket warmers, ready to be use and after energy release.

The bigger scale modern technical applications employ paraffins as phase change materials that can be tuned to certain melting ranges. However, the use of paraffin has a couple of disadvantages: Firstly, paraffins are petroleum-derived products and hence the use of these materials is directly linked to the price development of crude oil. Secondly, in order to achieve reliable phase change, they will have to be very pure and within the shirt chain length distribution, making them expensive. Thirdly, paraffin is eccentially candle by nature – extreme flammability makes them unusable in certain conditions and creates the fire hazard. Some formulations or encapsulation of paraffins can mitigate those problems, but on the other hand it reduces the content of energetically active material. Compared to paraffin, ionic liquids eliminate the fire hazard due to their fire-retardant nature.

Another class of phase change materials is salt solutions. The above-mentioned heat packs belong to this group. These materials offer the advantage that they are not petroleum products, but they have narrow temperature range, in which they can be used, especially compared to paraffin. In addition, due to the possibility of solvent evaporation or absorption of the humidity from the environment, often salt-based PCM have to be encapsulated. The encapsulation sometimes can disturb the heat transfer and therefore make the system less efficient. In addition, sometimes it is difficult to find material suitable for encapsulation, because heating of the system can result in solvent evaporation and pressure built up. And if the solvent evaporation happens in the system, this leads to the loss of energy (corresponding to the heat of evaporation). This is where ionic liquids offer a good alternative: owning to their negligible vapour pressure, they would neither be prone to overpressures, nor evaporation related energy loss. In addition, salt solutions often suffer from supersaturation and require additives for the crystallisation enhancement (e.g. small metal plate inside of the pocket warmer, which breaks quite easily and makes system unusable), whereas some ionic liquid have clean transition from liquid to solid state and avoid this problem.

Text: Dr. Svetlana Cadu, Iolitec GmbH, 2018