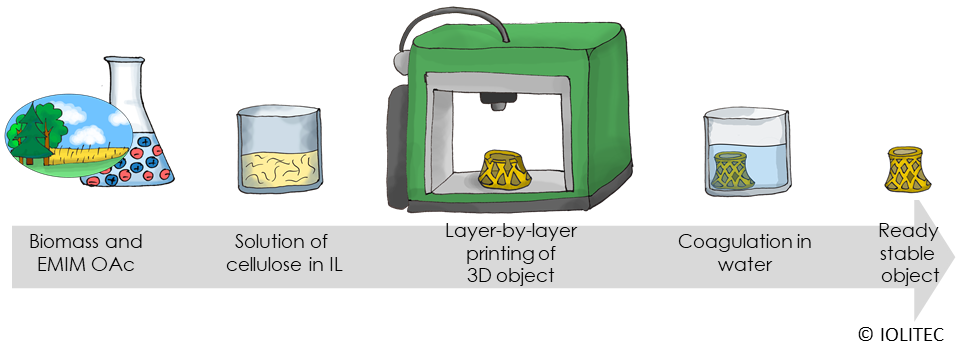

Nowadays, the precision and operational ease of three-dimensional printing have established this technique as the method of choice for fast production of complicated structures. As the field grows and develops, new materials are being applied. Typically, 3D printing uses metals, mineral materials or thermoplasts (polymers that can be processed at higher temperatures). Biomass, on the other hand, is being “produced” on a huge scale, but intrinsic lability of glycoside bond between sugar monomers of cellulosic materials results in decomposition upon heating. Hence, 3D printing of this abundant material was held back by the lack of technique that would allow its layer-by-layer application in a liquid state, followed by solidification.

Some of the cellulose esters had sufficient solubility for 3D printing application, but native cellulose was unreachable for a long time. However, ionic liquids, like EMIM OAc, EMIM DEP, BMIM Cl, established themselves as versatile solvents for biopolymer dissolution, fractionalisation and purification. This also opened new avenues for application included.

ILs can dissolve cellulose in quite high concentrations, but the fact that obtained solutions are very viscous is often seen as a drawback. Luckily, high viscosity plays a beneficial role in 3D printing, allowing printed structure to be stable in all three dimensions during printing process. Furthermore, long chains of cellulose offer shear thinning properties to its solution.[1] Due to disruption of hydrogen bonding network and subsequent reorientation of polymer molecules, viscosity of IL/cellulose solution decreases under high shear. This property removes the need of complicated printing nozzle structures, but usual syringe pump is sufficient for printing the solution. The viscosity of the solution quickly goes back to very high, as soon as it has been printed, and that helps with dimensional stability of the product.

On the other hand, it is known that organic solvents can be added to cellulose solutions in ILs to make them less viscous. Compatibility of the viscosity of obtained solutions with standard ink-jet 3D printer allows for easy printing of cellulosic materials as well.[2]

Scheme 1. 3D printing of cellulose solution in EMIM OAc.

But how can we get from cellulose solution in the solvent that never evaporates back to cellulose? Easily enough, treating with water removes ionic liquids and results in cellulose coagulation. The obtained structures are stable, and being composed of cellulose are also biocompatible, biodegradable and overall green. They can find applications in biomedical field and as new generation of smart materials.

If you would like to discuss cellulose dissolution and 3D printing possibilities with ionic liquids, please feel free to contact us. We provide not only standard ionic liquids for cellulose dissolution, but also customized products designed for specific applications.

Text and illustration: Dr. Svetlana Cadu, Iolitec 2019.